|

Feature Feature |

|

Result Result |

|

|

|

|

|

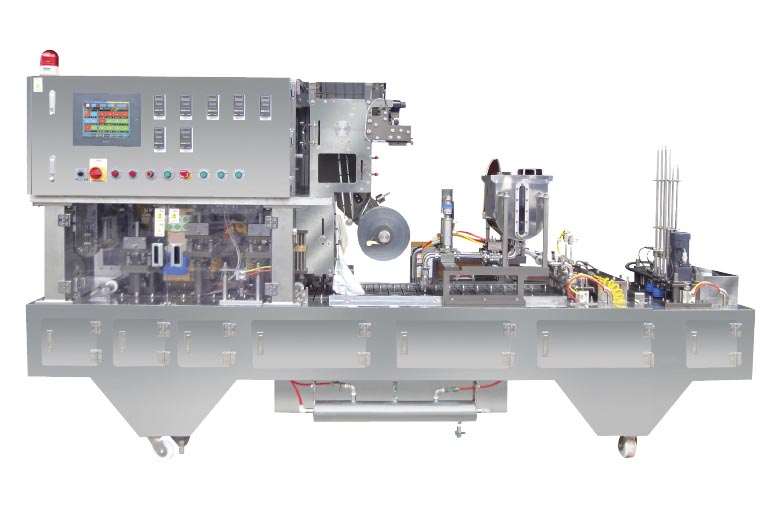

- It is applicable for gargle liquids and creams packing.

- As for sealing pressure, the powerful air cylinder, Double System, has been adopted.

- Sealing is done twice and attachment/detachment of a sealing bar can be done with ease for it is a rail

type.

- As the operation unit and the electric box located at the upper part of the machine, so water cleaning is

possible.

- Mold transport can be done in Steps and the water won’t overflow even if it fills up a container.

- For accurate sealing, the seal bar has a 360-degree cushion.

- Each unit holds independent functions and has been minimized in mechanical defects.

- A flashing light is turned on 2 minutes before the film is finished. When the films are completely consumed,

the machine will stop at its designated position. |

|

|

Specification Specification |

|

| Packing row |

2~8 Row (production option) |

| Capacity |

25~30 EA/min (on 1 row) |

| Date printer |

Jet Printer & Others Date Printer Option |

| Packing size |

W : 20~150 ×L : 20~200mm (option) |

| Filling capacity |

20~200g (option) |

| Electric Power |

220/380V, 3P, 50/60Hz |

| Compressed Air |

5~7kgf/cm2 , 500ℓ/min |

|

Contents Contents |

|

| Gargle liquid, for samples, jelly, Yoplait-type yogurt |

Packing material Packing material |

|

| AL+PE, OPP+PE, NY+PE, Other relevant packing papers with 3 sides sealed available for thermal sealing | |

|